Tannery wastes containing chromium are toxic for the micro-organisms and, hence, cannot be suitably treated by aerobic or anaerobic biological processes. For this purpose, the electrolytic process has been tried and has worked out satisfactorily. In this process, the waste is passed through sand beds to remove suspended particles like flesh, hair, etc.

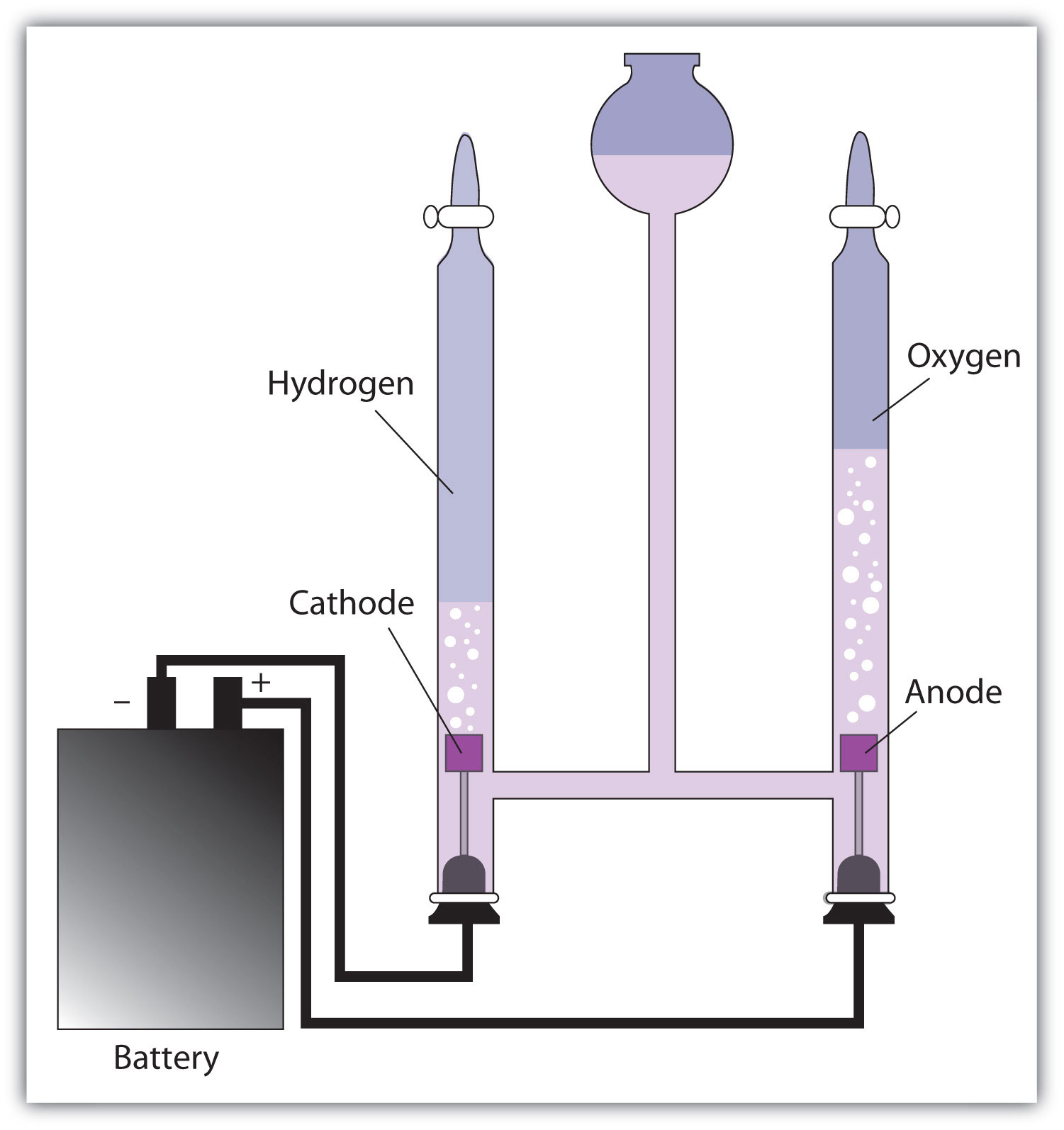

After adjusting pH to 3.5, the liquor is passed through an “Electrolyzing Column”. A current of 4 amperes at 11 volts is maintained between the electrodes. The dissolved organics are oxidized by the nascent oxygen produced, and suspended solids float out with the evolving hydrogen bubbles.

The electrolyzed liquor, after sand bed Alteration, can be recycled for tanning purposes. The solid materials involved in a typical tannery and their environmentally sound utilization.

ADVERTISEMENTS:

The practice suggested will not only eliminate associated health hazards but will also provide variable materials in some cases.

Screening, sedimentation, neutralization and anaerobic and aerobic biological processes for the treatment of tannery waste are well-established. As pointed out earlier, the characteristics of effluents vary widely from tannery to tannery. Hence, a certain amount of design calculation and modifications of process parameters are necessary in each case.

There are a few small tanneries, for which it is not easy to go in for pollution abatement. In such cases, it is advisable to have common arrangements for abatement, whereby the cost-benefits may be divided in proportion to the amount of effluents discharged.

ADVERTISEMENTS:

Regarding chrome tanning, it may be pointed out that chromium is non-renewable material. The importance of recycling is obvious for two important reasons. Firstly, some of the heavy metals, e.g., cadmium, lead, arsenic and chromium, which are dumped into natural streams, are serious pollutants.

Secondly, the resources of such non-renewable materials are in limited supply. For example, the world’s known reserves of chromium are about 775 million metric tonnes, of which about 1.86 million metric tonnes are mined annually at present.

Thus, at the current rate of use, known reserves would last about 420 years. Under the assumption of constant use, the linear depletion of chromium reserves would be expected. The actual world consumption of chromium is increasing, however, at the rate of 2.5 percent annually.

If the growth rate continues to increase at this rate, it will deplete the resource, not in 420 years but in just 95 years. If it is assumed that reserves yet undiscovered could increase the present known reserves by a factor of five, thus, extending the lifetime of the reserves only from 95 to 154 years.

ADVERTISEMENTS:

Even if it were possible from 1970 onwards to recycle 100 percent of the chromium so that none of the initial reserves were lost, the demand would exceed the supply in 235 years.

Chromium is definitely one of the most serious pollutants known. Most of the natural streams do not have any further assimilation capacity and, hence, cannot be used for the disposal of such materials any longer.

The natural stream has all along been used as an open dump of effluents. The irreversible change in the eco-system, due to an over-discharge of effluents is responsible for this alarming situation.

It is, therefore, equally essential to consider the assimilation capacity vis-a-vis the total pollution load while deciding the degree of treatment for effluents.